|

|

|

|

Citect – USA

Pushing the OPC Envelope with the OPC DataHub

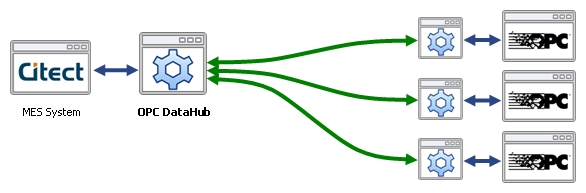

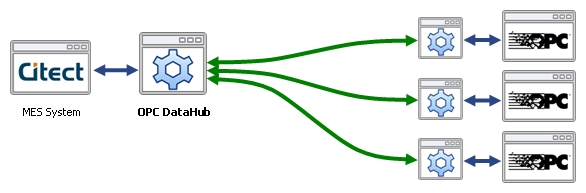

A major battery manufacturing plant in the United States was recently faced with an interesting data integration challenge. Management needed access to data coming from a large number of different processes. Over 220 OPC-enabled field devices across the plant had to be connected to a single Citect MES system. The many OPC servers used for these connections are unique in that their data set is very dynamic. From one minute to the next any of the 220 devices may be present or absent in the data set.

“Our challenge was to provide data from our dynamically changing OPC servers to a Citect system that is designed to work with a fixed data set,” said the company project leader. They decided to bring in a team from Citect to come up with a solution.

Citect, of Schneider Electric, is well known in the industrial process control world for their line of automation and control software solutions, particularly their MES systems. Dan Reynolds, the team leader for Citect, had heard about the OPC DataHub through his support department, and thought it might work. They configured the OPC DataHub for OPC tunneling, to communicate across the network without the hassles of DCOM. And, thanks to the OPC DataHub's unique approach to OPC tunneling, Dan found that it also solved the problem of providing a fixed data set.

“Our challenge was to provide data from our dynamically changing OPC servers to a Citect system that is designed to work with a fixed data set,” said the company project leader. They decided to bring in a team from Citect to come up with a solution.

Citect, of Schneider Electric, is well known in the industrial process control world for their line of automation and control software solutions, particularly their MES systems. Dan Reynolds, the team leader for Citect, had heard about the OPC DataHub through his support department, and thought it might work. They configured the OPC DataHub for OPC tunneling, to communicate across the network without the hassles of DCOM. And, thanks to the OPC DataHub's unique approach to OPC tunneling, Dan found that it also solved the problem of providing a fixed data set.

|

|

|

| |

“The OPC DataHub mirrors data across the tunnel,” said Dan, “so the Citect system sees a constant data set. When a device goes offline, the tag remains in the OPC DataHub. Just the quality changes from ‘Good’ to ‘Not Connected’.” Confident in their approach, the Citect team moved the testing from their location to the battery plant. But they soon found themselves faced with another challenge.

The production system is designed so that a field device can add or remove OPC items at any time. So, not only the OPC servers, but individual tags can suddenly appear or disappear from the system. When a new tag comes online, the server updates its tag count, but doesn't say that a new value is available, because the OPC specification doesn't require a server to say when a new point is created. This looked like a show-stopper for the configuration team. They knew that there is no OPC product on the market that can deal with that kind of behavior. Continually rereading the data set was not possible, because new points may be added during the read. So Dan got in touch with Cogent, and working together they came up with a plan.

The solution was two-fold. First, the device behavior was modified to compact the tag add/delete cycle to a limited time. Then Cogent wrote a DataHub script that monitors a few OPC server tags, and when these tags change, a time-delayed function in the script re-reads the server’s data set. The scripted time delay allows for all the new points to be added before the data set is reread, and the OPC DataHub thus discovers all of the new data as soon as it all becomes available.

“We are pleased with the performance of the OPC DataHub for this application,” said Dan Reynolds. “There is no way we could have done this project with any other OPC tunneling product, or combination of products.”

“The Cogent software has become an integral part of our MES solution,” said the project leader. “Without the OPC DataHub, we would not be getting reliable data. If we hadn’t had it, our MES integration project would probably have come to a halt.”

|

|

|

“Our challenge was to provide data from our dynamically changing OPC servers to a Citect system that is designed to work with a fixed data set,” said the company project leader. They decided to bring in a team from Citect to come up with a solution.

Citect, of Schneider Electric, is well known in the industrial process control world for their line of automation and control software solutions, particularly their MES systems. Dan Reynolds, the team leader for Citect, had heard about the OPC DataHub through his support department, and thought it might work. They configured the OPC DataHub for OPC tunneling, to communicate across the network without the hassles of DCOM. And, thanks to the OPC DataHub's unique approach to OPC tunneling, Dan found that it also solved the problem of providing a fixed data set.

“Our challenge was to provide data from our dynamically changing OPC servers to a Citect system that is designed to work with a fixed data set,” said the company project leader. They decided to bring in a team from Citect to come up with a solution.

Citect, of Schneider Electric, is well known in the industrial process control world for their line of automation and control software solutions, particularly their MES systems. Dan Reynolds, the team leader for Citect, had heard about the OPC DataHub through his support department, and thought it might work. They configured the OPC DataHub for OPC tunneling, to communicate across the network without the hassles of DCOM. And, thanks to the OPC DataHub's unique approach to OPC tunneling, Dan found that it also solved the problem of providing a fixed data set.